- Events

- Australia Day

- Bastille Day

- Burns Night

- Christmas

- Day of the Dead

- Eurovision

- Festivals / Summer

- Halloween

- Halloween Accessories

- Nativity

- Oktoberfest

- Olympics

- Pride

- Red Nose Day

- School Play Costumes

- St Andrew's Day

- St Davids Day

- St Georges / England Supporters

- St Patricks Day

- Six Nations Rugby

- Stag Do

- Summer

- Thanksgiving

- VE Day

- World Book Day

- Adult World Book Day Costumes

- 4th July

- Themes

- Animals

- Around The World

- Book Characters

- British

- Chocolate Factory

- Cops & Robbers

- Cosplay

- DC

- Doctors and Nurses

- Fairytale

- Funny / Novelty

- Gangster

- Harry Potter

- Hawaiian / Summer

- Heroes and Villains

- Historical

- Army, Air Force & Naval

- Mexican Fiesta

- Pick Me Up

- Pink Cowgirl Hat Aesthetic

- Pirates

- Popstars and Celebrities

- Pre Historic

- Religious

- Sexy Costumes

- Sports

- Star Wars

- Steampunk

- Suits

- Tiger King

- TV, Film and Game

- Wild West

- Wizard of Oz

- Wizards & Witches

- 2000s

- 1990s

- 1980s

- 1960s 1970s

- 1950s

- 1940s

- 1920s

- Cosmetics

- Body Crayons

- Eye Liner

- Fabric Paint

- Face & Body Paint

- Face Jewels

- Fake Blood

- FX Fluids

- Glitter Fixatives

- Glitter Gel

- Glitter Shaker

- Hair Colour Spray

- Hair Gel

- Hair Streaks

- Lipgloss

- Lipstick

- Lip Tattoos

- Loose Glitter

- Mascara

- Nail Polish

- Pigment Shakers

- Pro Face Paint Cake Pots

- Scars, Wounds, Prosthetics & FX

- Accessories

- Bandanas & Scarves

- Belts

- Braces

- Capes

- Elf Accessories

- Eye Lashes

- Facial Hair

- Feather Boas

- Glasses

- Gloves

- Guns, Weapons & Swords

- Hats & Headwear

- Hosiery

- Inflatables

- Jewellery

- Masks

- Masquerade Masks

- Nipple Pasties

- Pacifiers

- Props

- Sets & Kits

- Shoe Covers

- Shoes / Boots

- Sleeves

- Teeth

- Ties & Bowties

- Tutus & Underskirts

- Wigs

- Wings & Wands

- Other

- Gifts by Category

- Alternative

- Balloon Dog Sculptures

- Batteries

- Colouring Books

- Decorative Accessories

- Food & Drink

- Fragrance

- Gadgets & Tech

- Gift Sets

- Gifts for the Home

- Homeware

- Jewellery

- Keepsakes

- Knitting Wool

- Life

- Luggage & Suitcases

- Miscellaneous

- Ornaments

- Personalised Gifts

- Puzzle Books

- Puzzles

- Slippers

- Smoking

- Stationery

- Umbrellas

- Vehicle

- Wallets & Purses

- Warmies

-

- Australia Day

- Bastille Day

- Burns Night

- Christmas

- Day of the Dead

- Eurovision

- Festivals / Summer

- Halloween

- Halloween Accessories

- Nativity

- Oktoberfest

- Olympics

- Pride

- Red Nose Day

- School Play Costumes

- St Andrew's Day

- St Davids Day

- St Georges / England Supporters

- St Patricks Day

- Six Nations Rugby

- Stag Do

- Summer

- Thanksgiving

- VE Day

- World Book Day

- Adult World Book Day Costumes

- 4th July

-

- Animals

- Around The World

- Book Characters

- British

- Chocolate Factory

- Cops & Robbers

- Cosplay

- DC

- Doctors and Nurses

- Fairytale

- Funny / Novelty

- Gangster

- Harry Potter

- Hawaiian / Summer

- Heroes and Villains

- Historical

- Army, Air Force & Naval

- Mexican Fiesta

- Pick Me Up

- Pink Cowgirl Hat Aesthetic

- Pirates

- Popstars and Celebrities

- Pre Historic

- Religious

- Sexy Costumes

- Sports

- Star Wars

- Steampunk

- Suits

- Tiger King

- TV, Film and Game

- Wild West

- Wizard of Oz

- Wizards & Witches

- 2000s

- 1990s

- 1980s

- 1960s 1970s

- 1950s

- 1940s

- 1920s

-

- Body Crayons

- Eye Liner

- Fabric Paint

- Face & Body Paint

- Face Jewels

- Fake Blood

- FX Fluids

- Glitter Fixatives

- Glitter Gel

- Glitter Shaker

- Hair Colour Spray

- Hair Gel

- Hair Streaks

- Lipgloss

- Lipstick

- Lip Tattoos

- Loose Glitter

- Mascara

- Nail Polish

- Pigment Shakers

- Pro Face Paint Cake Pots

- Scars, Wounds, Prosthetics & FX

-

- Bandanas & Scarves

- Belts

- Braces

- Capes

- Elf Accessories

- Eye Lashes

- Facial Hair

- Feather Boas

- Glasses

- Gloves

- Guns, Weapons & Swords

- Hats & Headwear

- Hosiery

- Inflatables

- Jewellery

- Masks

- Masquerade Masks

- Nipple Pasties

- Pacifiers

- Props

- Sets & Kits

- Shoe Covers

- Shoes / Boots

- Sleeves

- Teeth

- Ties & Bowties

- Tutus & Underskirts

- Wigs

- Wings & Wands

- Other

-

- Alternative

- Balloon Dog Sculptures

- Batteries

- Colouring Books

- Decorative Accessories

- Food & Drink

- Fragrance

- Gadgets & Tech

- Gift Sets

- Gifts for the Home

- Homeware

- Jewellery

- Keepsakes

- Knitting Wool

- Life

- Luggage & Suitcases

- Miscellaneous

- Ornaments

- Personalised Gifts

- Puzzle Books

- Puzzles

- Slippers

- Smoking

- Stationery

- Umbrellas

- Vehicle

- Wallets & Purses

- Warmies

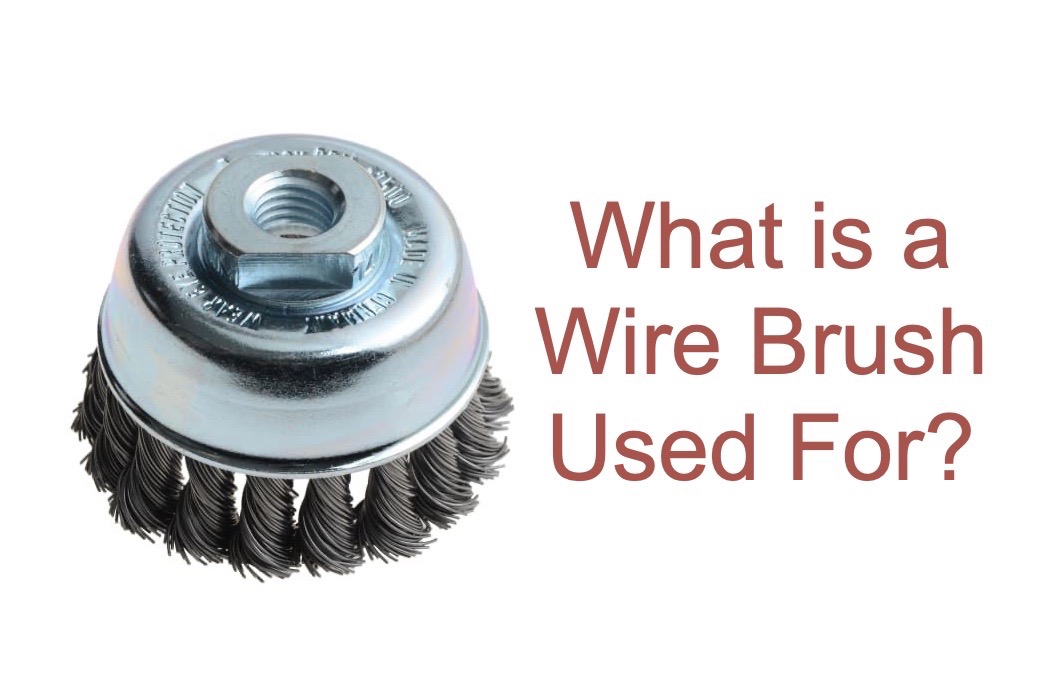

What is a Wire Brush Used For?

by Darren Butler

Last updated: Aug 08, 2025

Wire brushes are versatile tools widely used across various industries and household tasks. Whether you're cleaning, deburring, or surface preparation, the wire brush is often the go-to solution. Comprising steel, brass, or stainless steel bristles, these tools come in numerous shapes and sizes, each suited for specific purposes. In this blog post, we'll explore the different types of wire brushes, how they function, and the wide range of applications they serve. From industrial applications to DIY projects, wire brushes are invaluable tools in a variety of settings, making them essential in both professional and home environments.

Types of Wire Brushes and Their Applications

Wire brushes come in several forms, including hand-held brushes, wheel brushes, cup brushes, and power tool attachments. Each type has its own unique use, and depending on the application, the type of wire, brush shape, and size can significantly impact the outcome of a task.

Hand-Held Wire Brushes

Hand-held wire brushes are among the most common and simplest forms of wire brushes. They are used for manual cleaning, rust removal, surface preparation, and polishing. These brushes typically come with a wooden or plastic handle and are used in a back-and-forth motion to remove debris, dirt, paint, or rust from surfaces. Hand-held wire brushes are ideal for smaller, more detailed tasks or when precise control is needed. They are particularly effective for cleaning small areas, such as welding seams, tool maintenance, or even scrubbing stubborn dirt from various surfaces.

The versatility of hand-held wire brushes allows them to be used on many materials such as metal, wood, brick, and stone. For instance, they are great for cleaning and preparing metal surfaces before painting or welding, as well as cleaning tools and machinery.

Wire Brush Wheels

Wire brush wheels are a powerful tool for more demanding cleaning and surface preparation tasks. These brushes consist of a circular wire brush that is typically attached to a rotating power tool, such as an angle grinder or a drill. They are designed to be more efficient than hand-held wire brushes, offering a faster and more consistent cleaning solution.

Wire brush wheels are ideal for removing large amounts of rust, paint, and scale from metal surfaces, as well as cleaning and preparing welding seams. These brushes can also be used for surface deburring, which is the process of removing small bits of metal left over after machining. They are widely used in automotive repair, metalworking, and construction industries.

Cup Brushes

Cup wire brushes are similar to wire brush wheels but have a cup-shaped design. This design allows them to reach into corners, edges, and other hard-to-reach places. Like wire brush wheels, they are usually attached to power tools, but their cup shape makes them better suited for cleaning narrow spaces and edges. Cup brushes are commonly used for cleaning welds, removing rust from pipes, or preparing surfaces for coatings.

Cup brushes come in various sizes, from small models for precise tasks to larger ones for heavy-duty cleaning. The flexibility of cup brushes makes them a valuable tool in industries such as automotive, plumbing, and construction, where reaching tight spots is essential.

Power Tool Attachments

For more industrial applications, wire brushes can be used as attachments for power tools, such as drills, rotary tools, or angle grinders. These power tool attachments significantly increase the efficiency and speed of wire brushing tasks. Power tool wire brushes are designed to handle larger surface areas and tougher materials, making them ideal for heavy-duty cleaning tasks.

In industrial settings, these tools are used to remove tough coatings, scale, rust, and corrosion from large metal surfaces. Power tool wire brushes are commonly used in shipbuilding, automotive repair, construction, and manufacturing industries.

Materials of Wire Brushes

Wire brushes can be made from various materials depending on the task and the surface they are meant to clean. Steel wire brushes are the most common and are known for their toughness and durability. They are highly effective at cleaning hard surfaces and removing heavy rust and paint. However, steel brushes can be too harsh for delicate surfaces, so it's important to choose the right wire material based on the task at hand.

Brass wire brushes are softer than steel brushes and are ideal for cleaning softer metals such as brass, aluminium, or gold. They are also commonly used in electrical work, as they do not spark, making them a safer option when cleaning or polishing electrical components. Brass brushes are effective at cleaning delicate surfaces without causing damage or scratching.

Stainless steel wire brushes are ideal for both general-purpose and specialised tasks. They are resistant to corrosion and rust, making them suitable for outdoor or marine applications. Stainless steel brushes can be used for cleaning a variety of materials, including stainless steel, iron, and non-ferrous metals.

Common Uses of Wire Brushes

- Cleaning and Rust Removal: One of the most common uses of wire brushes is for cleaning rust from metal surfaces. They can be used to scrub off rust from machinery, vehicles, and tools, preparing these items for restoration or maintenance.

- Surface Preparation: Before welding or painting, metal surfaces need to be cleaned and prepared to ensure proper adhesion. Wire brushes are often used in this process to remove any dirt, grease, or oxidation. They also help remove scale and other contaminants, providing a clean surface for the new material or coating.

- Deburring: Deburring is the process of removing sharp edges and small metal fragments from a surface after it has been machined or cut. Wire brushes are commonly used to deburr metal parts, such as gears, pipes, and structural components.

- Polishing: Wire brushes are also used for polishing metal surfaces. Brass and stainless steel wire brushes, in particular, are ideal for creating a smooth, shiny finish on metal objects. Polishing with wire brushes helps maintain the aesthetic quality of items like jewellery, metal sculptures, and even kitchen appliances.

- Cleaning Pipes and Tubes: Cup and wheel wire brushes are often used to clean the inside of pipes and tubes, especially in industrial settings. They can remove scale, dirt, and other contaminants, ensuring the smooth flow of liquids or gases through the pipes.

- Welding and Soldering: Wire brushes are frequently used in welding to clean the surfaces of metal before the welding process begins. Removing contaminants ensures better weld penetration and improves the overall strength and quality of the weld.

Conclusion

Wire brushes are essential tools in a variety of industries and household tasks. Their versatility and ability to handle different materials make them indispensable for surface preparation, cleaning, deburring, and polishing. Whether you are working on a DIY project or in a professional setting, understanding the different types of wire brushes and their applications can help you select the right tool for the job. From small hand-held brushes to large power tool attachments, wire brushes continue to serve as invaluable tools in maintaining and restoring various surfaces.

- Menu

- Fancy Dress

- Electronics & Gaming

- Clothing

- Pet Products

- Garden

- Tools & DIY

- Home & Leisure

- Gifting & Parties

- Toys

- Information

- About Us

- Become a seller

- Affiliate Programme

- Frequently Asked Questions

- Returns and Refunds

- Terms And Conditions

- Privacy Policy

- View our blog

- Featured

- View more

- Customer Care

- [email protected]

- +44 (0) 1702 617821

- ILFD Group Ltd T/A Cazaar®

- Company Number: 07034824